Shrink wrapping has become an essential packaging solution across multiple industries, including food, pharmaceuticals, electronics, and retail. It provides a cost-effective and efficient way to protect and secure products while enhancing their shelf appeal. At the heart of this process is the shrink wrap packaging machine, a sophisticated piece of equipment that ensures the proper application of shrink film. But how exactly does shrink wrapping work? Let’s dive into the science behind this widely used packaging method.

Understanding Shrink Wrapping

Shrink wrapping is a packaging technique that involves wrapping a product in a polymer plastic film and then applying heat to shrink the film around the item. This creates a tight, secure seal that protects the product from dust, moisture, and external contaminants.

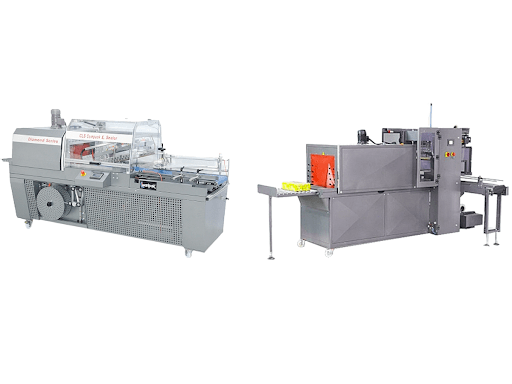

Key Components of a Shrink Wrap Packaging Machine

A shrink wrap packaging machine consists of several essential components that work together to achieve a seamless wrap:

- Film Dispenser – Holds the shrink wrap film, which is typically made of polyethylene (PE), polyolefin (POF), or polyvinyl chloride (PVC).

- Sealing System – Uses heat to cut and seal the film around the product.

- Heat Application System – Shrinks the film tightly around the item, ensuring a secure fit.

- Conveyor System – Moves the product through various stages of the wrapping process.

The Science Behind Shrink Wrapping

Shrink wrapping relies on two fundamental scientific principles: thermoplastics behavior and heat-induced polymer contraction.

1. Thermoplastic Behavior

Shrink wrap films are made from thermoplastics, a category of polymers that become pliable when heated and return to a solid state when cooled. The molecular structure of these plastics allows them to stretch when heated and shrink back upon cooling, enabling a firm and secure wrap around the product.

2. Heat-Induced Polymer Contraction

During the manufacturing process, shrink films are stretched and oriented in a specific direction. When heat is applied, the film’s molecules return to their original unstretched state, causing the plastic to shrink. This shrinkage occurs in two directions:

- Unidirectional shrink wrap – Shrinks in one direction, ideal for specific packaging needs.

- Bidirectional shrink wrap – Shrinks uniformly in all directions, providing a more even wrap.

How Shrink Wrap Packaging Machines Work

A shrink wrap packaging machine follows a step-by-step process to wrap products efficiently. Here’s how it works:

1. Wrapping the Product

The product is placed on the machine’s conveyor system, where it is wrapped in a plastic film. Some machines use a manual L-bar sealer, while automated systems use continuous flow wrapping.

2. Sealing the Film

The sealing system applies heat to cut and seal the edges of the film, ensuring the product is fully enclosed. This can be achieved using impulse sealing, constant heat sealing, or ultrasonic sealing.

3. Heat Shrinking

Once sealed, the product moves into a heat chamber or a heat shrink tunnel machine. The applied heat causes the film to shrink and conform tightly around the product. This process can use various heat sources, such as:

- Hot air blowers – Distribute heated air evenly across the film.

- Infrared radiation – Uses electromagnetic waves to heat and shrink the film quickly.

- Steam tunnels – Used for specialized shrink films requiring moisture control.

4. Cooling and Final Packaging

After shrinking, the package cools, allowing the film to set in place. The final result is a tight, durable, and professional-looking package ready for distribution.

Applications of Shrink Wrap Packaging Machines

Shrink wrapping is used in various industries due to its versatility and efficiency. Some common applications include:

- Food Packaging – Used for wrapping fresh produce, meats, and bakery items to enhance shelf life.

- Pharmaceutical Industry – Ensures tamper-proof packaging for medicines and medical devices.

- Retail and Consumer Goods – Protects and secures products like DVDs, toys, and electronics.

- Industrial Packaging – Used for bundling multiple products together, such as beverage packs and hardware tools.

Benefits of Shrink Wrapping

Shrink wrapping offers numerous advantages, making it a preferred packaging choice:

- Product Protection – Shields items from dust, moisture, and external damage.

- Enhanced Aesthetics – Provides a clear and glossy appearance, improving product presentation.

- Tamper Resistance – Makes it evident if a package has been opened or altered.

- Cost-Effectiveness – Uses minimal materials while reducing packaging waste.

- Versatility – Suitable for products of various shapes and sizes.

Conclusion

Shrink wrapping is a scientifically advanced and efficient packaging solution that relies on the unique properties of thermoplastics and heat-induced contraction. The shrink wrap packaging machine plays a crucial role in automating this process, ensuring high-speed, consistent, and secure packaging. As industries continue to demand reliable and cost-effective packaging solutions, innovations in shrink wrap technology, including advanced heat shrink tunnel machines, will further enhance the efficiency and sustainability of packaging operations.