Automation is revolutionizing industries, transforming traditional manufacturing processes into efficient, precise, and scalable operations. At the heart of this transformation lies vision system camera inspection, a technology that combines high-resolution imaging with intelligent software to ensure quality and accuracy across production lines. This article delves into the pivotal role of vision system cameras in automated inspection and their impact on industrial processes.

What is Vision System Camera Inspection?

Vision system camera inspection involves using cameras, sensors, and advanced algorithms to capture and analyze images of products in real-time. These systems compare the captured images against predefined criteria to identify defects, measure dimensions, and validate the integrity of products. The automation of this process eliminates human error, enhances efficiency, and maintains consistency in quality control.

Key Functions of Vision System Camera Inspection

-

Defect Detection

Vision systems excel at identifying a wide range of defects, including cracks, discoloration, deformities, and contamination. By analyzing every product at high speed, they ensure that only undamaged items proceed through the production line. -

Dimensional Measurement

Precision is critical in industries such as electronics and automotive. Vision system cameras measure dimensions and tolerances with unmatched accuracy, ensuring components meet exact specifications. -

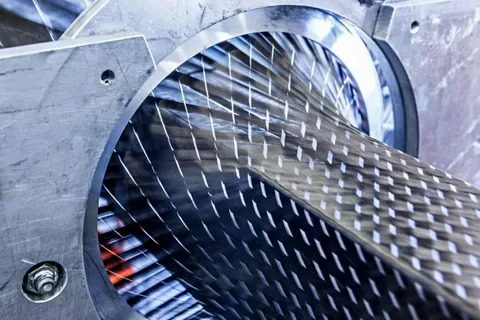

Surface Inspection

Detecting surface imperfections such as scratches, dents, or irregular textures is another crucial function. Vision systems use advanced imaging techniques to inspect surfaces and ensure a flawless finish. -

Product Verification

Vision system cameras verify that products are correctly assembled, labeled, and packaged. This is particularly important in pharmaceuticals, where incorrect labeling or missing components can have serious consequences. -

Serialization and Traceability

In industries like pharmaceuticals and electronics, serialization ensures every product is uniquely identifiable. Vision systems enable accurate serialization and track-and-trace capabilities, helping prevent counterfeiting and ensuring regulatory compliance.

Industries Benefiting from Vision System Camera Inspection

1. Pharmaceuticals

Vision systems play a critical role in inspecting tablets, capsules, and vials for defects. They also ensure accurate labeling, serialization, and packaging, safeguarding consumer safety.

2. Automotive Manufacturing

From detecting flaws in engine components to verifying assembly accuracy, vision systems help maintain the safety and reliability of vehicles.

3. Electronics

Vision systems inspect intricate components such as circuit boards, connectors, and solder joints, ensuring that electronic devices perform flawlessly.

4. Food and Beverage

These systems check for proper sealing, labeling, and contamination in packaged goods, maintaining hygiene and consumer trust.

5. Textiles

Vision cameras detect weaving defects, color mismatches, and irregularities in fabric production, enhancing quality in the textile industry.

Benefits of Vision System Camera Inspection

-

Improved Accuracy and Consistency

By eliminating human error, vision systems provide consistent and reliable inspection results, even in high-speed operations. -

Cost-Effectiveness

Early defect detection minimizes waste, reduces rework, and prevents costly recalls, making vision systems a cost-effective solution. -

Increased Productivity

Automated inspection allows production lines to operate at higher speeds without compromising quality, boosting overall productivity. -

Data Analytics and Process Optimization

Vision systems generate detailed inspection data, enabling manufacturers to identify trends, optimize processes, and implement predictive maintenance.

Challenges in Vision System Camera Inspection

Despite their advantages, implementing vision systems can present challenges, including:

- Complex Calibration: Proper calibration of cameras and lighting is essential for accurate results.

- Environmental Factors: Dust, vibrations, and inconsistent lighting can affect performance, necessitating protective enclosures and controlled environments.

- System Integration: Seamless integration with existing workflows and machinery requires careful planning and expertise.

Collaborating with experienced solution providers can help manufacturers overcome these challenges and maximize the benefits of vision systems.

Future Trends in Vision System Camera Inspection

As technology evolves, vision systems are becoming more sophisticated and versatile. Key trends shaping the future include:

- AI and Machine Learning: Advanced algorithms enable systems to learn from data, improving their ability to detect complex defects and adapt to new inspection requirements.

- 3D Imaging: Three-dimensional vision systems offer enhanced accuracy in inspecting complex shapes and surfaces.

- Edge Computing: By processing data locally, edge computing reduces latency and enables faster decision-making.

- Integration with IoT: Vision systems integrated with IoT devices provide real-time monitoring and predictive analytics, further streamlining production processes.

Conclusion

Vision system camera inspection is at the forefront of automated quality control, offering unmatched accuracy, efficiency, and reliability. By automating inspection tasks, these systems enhance product quality, reduce costs, and enable manufacturers to meet the demands of modern markets.

As industries continue to embrace automation, the role of vision systems will only grow, driving innovation and excellence across sectors. Adopting vision system camera inspection is no longer a luxury—it’s a necessity for businesses aiming to remain competitive in today’s dynamic industrial landscape.