Introduction

In the manufacturing and metal finishing industries, shot blasting machines play a crucial role in surface preparation, cleaning, and finishing. These machines are essential for removing rust, scale, and contaminants from metal surfaces, thereby improving adhesion for coatings and extending the life of the treated components. However, the efficiency and durability of shot blasting machines are directly influenced by their quality. Investing in high-quality shot blasting machines ensures better performance, longer service life, and reduced maintenance costs. This article explores the importance of quality in shot blasting machines and its impact on performance and longevity. Shot Blasting Machine, Shot Blasting Machine Manufacturers, Robotic Shot Peening Machine, shot peening machine, Robotic Shot Peening Machine Manufacturers , Automatic Shot Blasting Machine, shot blasting machine manufacturers in india , shot peening machine manufacturers in india, shot blasting machine manufacturers in jodhpur, shot peening machine manufacturers, Shot blasting machine manufacturer, shot blasting machine manufacturers in asia, shot blasting machine manufacturers in australia,

https://sfecindia.net/

https://sfecindia.net/shot-peening-machine.html

https://sfecindia.net/robotic-shot-peening-machine.html

Understanding Shot Blasting Machines

Shot blasting machines use abrasive materials, commonly referred to as shot or grit, to clean or texture surfaces. These machines function by propelling the abrasive material at high speeds onto the target surface, effectively removing unwanted coatings, rust, and contaminants. Shot blasting is widely used in industries such as automotive, aerospace, construction, and shipbuilding, where metal surfaces require precise finishing.

Key Factors Determining Quality in Shot Blasting Machines

Material and Build Quality

- The durability of a shot blasting machine depends on the materials used in its construction. High-quality machines are built using wear-resistant alloys, hardened steel, and robust components that can withstand continuous exposure to abrasive materials.

- Poorly constructed machines may experience frequent breakdowns, requiring costly repairs and replacements.

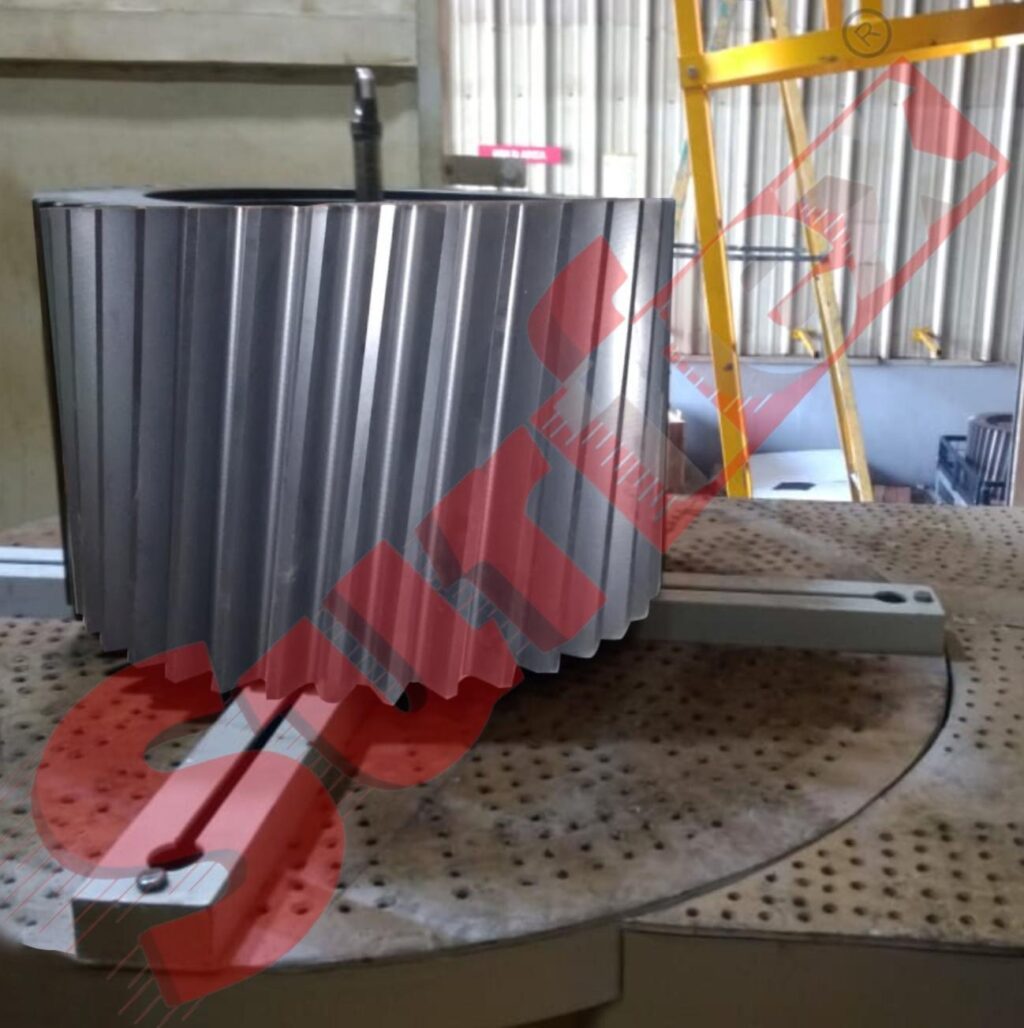

Blast Wheel Efficiency

- The blast wheel is a critical component that propels the abrasive material at high speeds. High-quality machines feature well-designed blast wheels made from durable materials, ensuring efficient energy transfer and uniform distribution of abrasives.

- Inferior blast wheels may lead to uneven blasting, higher energy consumption, and reduced overall performance.

Precision Control Systems

- Modern shot blasting machines come equipped with advanced control systems that allow operators to adjust parameters such as abrasive flow rate, pressure, and rotation speed.

- A high-quality control system ensures precise operation, preventing material wastage and achieving consistent surface finishes.

Abrasive Media Reclamation System

- Efficient abrasive recovery and recycling systems enhance the performance of shot blasting machines by reducing media consumption and operational costs.

- A superior quality reclamation system prevents contamination and extends the lifespan of the abrasive media, improving overall efficiency.

Dust Collection and Filtration

- Quality shot blasting machines incorporate advanced dust collection and filtration systems to ensure a cleaner working environment and comply with safety regulations.

- Poor filtration systems can lead to excessive dust accumulation, affecting both machine performance and workplace safety.

Impact of Quality on Machine Performance

Higher Productivity

- High-quality shot blasting machines deliver consistent and efficient performance, reducing processing time and increasing output.

- Advanced automation features and precision controls help achieve uniform blasting results, improving overall productivity.

Energy Efficiency

- Premium machines are designed to optimize energy usage, reducing power consumption while maintaining superior blasting performance.

- Inferior machines often require more energy to achieve the same results, leading to higher operational costs.

Minimized Downtime

- High-quality components and robust construction reduce the risk of breakdowns and unplanned maintenance, ensuring continuous operations.

- Downtime due to machine failures can lead to significant production delays and financial losses.

Enhanced Surface Finish Quality

- The precision and efficiency of a well-built shot blasting machine ensure a smooth and uniform surface finish, improving the adhesion of coatings and paints.

- Low-quality machines may produce uneven results, leading to rework and wastage of materials.

Longevity and Maintenance of Shot Blasting Machines

Use of High-Quality Components

- The longevity of a shot blasting machine depends on the durability of its components, such as blast wheels, nozzles, and liners.

- Investing in machines with high-quality parts reduces the frequency of replacements and extends operational lifespan.

Regular Maintenance and Servicing

- Even the best machines require routine maintenance to function optimally. Scheduled servicing, lubrication, and component inspections help prevent premature wear and breakdowns.

- High-quality machines are often designed with easy maintenance features, allowing quick access to replaceable parts.

Proper Handling and Operation

- Operator training and adherence to recommended usage guidelines are crucial for ensuring machine longevity.

- Mishandling or incorrect settings can lead to excessive wear and reduced machine lifespan.

Availability of Spare Parts and Support

- Leading manufacturers of high-quality shot blasting machines provide readily available spare parts and technical support, ensuring quick repairs and minimal downtime.

- Low-cost, inferior machines may lack after-sales support, leading to longer wait times for repairs and reduced productivity.

Cost Considerations: Quality vs. Initial Investment

Long-Term Cost Savings

- While high-quality shot blasting machines may have a higher initial investment, they offer significant cost savings over time through reduced maintenance, energy efficiency, and longer service life.

- Low-quality machines often incur frequent repair costs, downtime losses, and high energy consumption, making them costlier in the long run.

Return on Investment (ROI)

- Investing in a premium shot blasting machine ensures faster ROI by improving efficiency, reducing operational costs, and enhancing product quality.

- Businesses that prioritize quality in their machinery benefit from increased customer satisfaction and repeat business.

Conclusion

The role of quality in shot blasting machines cannot be overstated. High-quality machines provide superior performance, energy efficiency, and long-term reliability, ensuring uninterrupted operations and cost savings. Investing in a well-built shot blasting machine enhances productivity, reduces maintenance needs, and extends the machine’s service life. Manufacturers should carefully evaluate material construction, control systems, abrasive reclamation, and filtration systems when selecting a shot blasting machine to maximize performance and longevity. By prioritizing quality, businesses can achieve optimal results, enhance workplace safety, and improve overall profitability in their shot blasting operations.