The diverse industrial sectors are playing at the forefront of embracing technological advancements from the outset of mechanization to the modern era of industry. Several emerging technologies are driving the industry revolution nowadays. Holding hands with generative AI, the traditional manufacturing struggles of supply chain disruptions are replaced by automation. Generative AI is paving the way for enhanced productivity, improved customer service and a unique ecosystem—Gen AI in manufacturing streamlines challenges like accelerating design iterations and scaling production. Generative AI in Smart Manufacturing harnesses real-time sensor data and different data streams to enhance the latest processes.

As per the latest Rockwell Automation’s 9th Annual State of Smart Manufacturing Research Report 2024, it has been stated that gen AI is any manufacturer’s best investment priority for another year. In this blog post, we are going to explore the capability of generative AI in the manufacturing sector and emphasize the advantages of smart manufacturing companies. Generative AI has ushered in an era where machines act as creative partners that innovate, ideate and generate novel solutions depending on the data they have trained on.

The importance of generative AI in smart manufacturing

In the smart manufacturing industry, generative AI revolutionizes industrial operations by optimizing the production process and improving the overall organizational efficiency. By harnessing the real-time data from interconnected devices. AI automates workflows, accelerates decision-making and lowers overall downtime. Generative AI replaces traditional methods with rapid iteration cycles enabling engineers to quickly explore different design options in natural language before fine-tuning them with conventional tools.

What is the scope of generative AI in manufacturing?

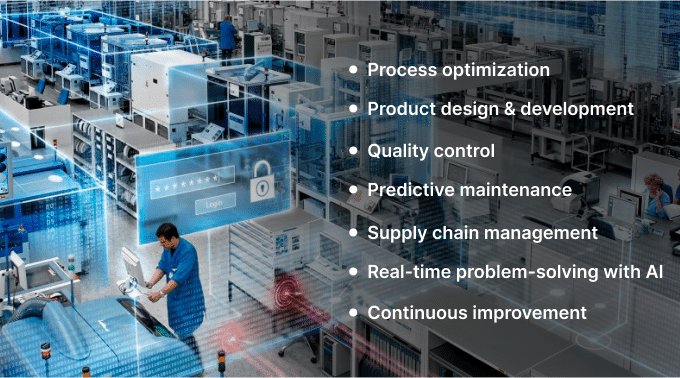

Gen AI is empowered to create results depending on insights and patterns curated from vast amounts of data. Across the manufacturing domains, it paves the way for unprecedented opportunities for efficiency and innovation employed in aspects like process optimization, product design, quality control and many more. In this context, let’s take a look at the different applications of GenAI in manufacturing.

Process optimization

Generative AI can suggest optimized manufacturing processes comprising production schedules, machine settings, and resource allocation. It results in enhanced efficiency and improved productivity.

Product design & development

Gen AI can effectively create & recreate product designs considering multiple parameters comprising performance requirements and other manufacturing constraints. This potential accelerates the design process for manufacturers resulting in unique solutions.

Quality control

Gen AI is increasingly influential in creating smart models for detecting and predicting defects in real time. It ensures superior product quality by diminishing the time and cost relating to quality control.

Predictive maintenance

Generative AI proves influential in predicting errors in maintenance and equipment failures in real time. It ensures that manufacturing companies can implement proactive maintenance strategies effectively diminishing downtime.

Supply chain management

Gen AI models are effectively beneficial for inventory optimization, demand forecasting and risk assessment. It allows manufacturing organizations to navigate complex global supply chains.

Real-time problem-solving with AI

Manufacturing facilities generally confront challenges such as a lack of real-time visibility and equipment glitches. With the integration of Generative AI, manufacturing facilities can leverage real-time data from maintenance logs for identifying patterns and aberrations. Implementing preventive maintenance empowers vendors to step in immediately and Gen AI puts forth its plan of action for addressing the glitches.

Continuous improvement

Generative AI enforces continuous learning and improvement for businesses. The technology is empowered to generate insights depending on real-time data and feedback. It enables manufacturers to meet current industry standards and anticipate future expectations.

How is generative AI effective in manufacturing & related business?

Smart factories can significantly reduce overall organizational expenses ensuring that the right products are available at the right time in the market. If you are looking for the right AI development company, then you should be going through the major criteria that make the company right for your project. As of the frontline, manufacturing companies should prioritize investments in Generative AI services to stay ahead of the curve.

Strategic decision-making

Gen AI comes with an inner potential to analyze large volumes of data quickly administering actionable insights to manufacturing facilities for strategic decision-making.

Resource optimization

Nowadays, manufacturing facilities are embracing generative AI which is turning out to be a transformative force in the industry. The innovation empowers manufacturing companies to recognize areas of resource optimization and costs too. Gen AI technology can be implemented harnessing advanced algorithms to administer a holistic view of resource utilization resulting in a streamlined operational process.

Advanced efficiency

Automating a multitude of aspects of generative AI supports the entire framework right from workflow optimization, ideation, and design to supply chain management and quality control. It helps in boosting product development and advancing operational efficiency.

Probable use cases of generative AI in manufacturing

Generative AI application mainly relies on advanced technologies such as Generative adversarial networks (GANs) which allow machines to create new designs by learning from different patterns in extensive datasets. Automotive manufacturing facilities use GANs for generating and refining cars depending on consumer preferences.

Computer vision

Vision AI assists in quality control detecting flaws during production, and gen AI paired with computer vision assists in simulating corrections effectively lowering defects without human intervention.

Scalable solutions for smart manufacturing

Having growing complexities, manufacturers require a comprehensive solution for ensuring a seamless and scalable deployment across different use cases.

Final thoughts

Gen AI can be integrated into the manufacturing processes by streamlining them through a technological stride. The technology empowers smart manufacturing by generating innovative insights. It helps in improving the design process, boosting product development and optimizing supply chain operations. The transformative technology enables manufacturers to enhance current operations and unveil new possibilities for creating value. It is important for manufacturing facilities to prioritize investments in Generative AI services to stay ahead of the curve and scale businesses in an ever-evolving business scenario.

To know more about Generative AI, unveil the real value of generative AI in manufacturing and advancing the efficiency of our AI-driven manufacturing data analytics solutions.