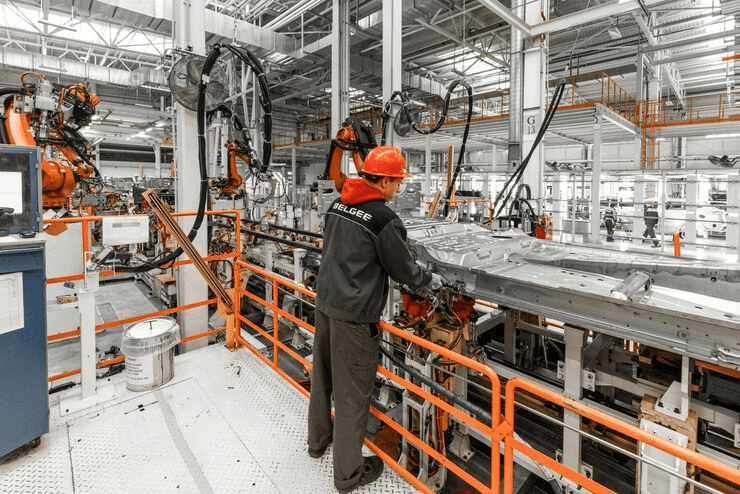

Harness assemblies play a significant role in offering error connectivity for automotive, industrial automation, robotics, and renewable energy. At SINNHONG ELECTRONICS, a leading name among Harness Manufacturing Companies In Vietnam, we specialize in crafting high-quality cable and wire harness assemblies that offer superior performance and reliability. Our products are known worldwide in Dongguan, China, and Vietnam facilities and can withstand anything with their high durability and precise engineering.

Proper maintenance practices help in making your harness assemblies last a long time and function adequately. Here are some primary tips for ensuring longlasting harness assemblies:

- Routine Inspection and Testing

Routine inspections can help in identification of wear or corrosion or other issues while it is early enough to prevent costly failures. Checking connectors, wires and insulation for signs of damage, testing with specialized high-end equipment ensures optimal performance and long life.

As one of the top Harness Manufacturing Companies In Vietnam, our custom cable assemblies are tested to international standards such as ISO 9001, UL, and MIL-SPEC, so you’ll get products built for reliability.

- Protect against Environmental Hazards

The harsh outdoor or industrial environment will damage wire harness integrity from heat, moisture, and chemicals. So use weather-resistant sealed designs.

We have IP67-rated control cables, corrosion-resistant marine wire assemblies, and high-temperature assemblies so that our solutions can thrive in demanding environments.

- Proper Cable Management

Keep the cables untangled with minimal stress or twist, keep them in place with cable ties and protect them with protective tubes to prevent wear from vibrating and moving around.

Being one of the premier Harness Manufacturing Companies In Vietnam, our products like vibration-resistant wiring harnesses as well as compact wire looms can be implemented on applications requiring flexibility and elasticity thereby lasting longer.

- Avoid Overloading

Electrical overloads can lead to overheating and damage. Choose harness assemblies with adequate power-handling capacity, and regularly check for any signs of electrical stress.

We provide customizable wire sizes for varied power requirements, helping you select the ideal harness for your needs.

- Use High-Quality Materials

Harness longevity starts with the right materials. Choose assemblies with durable wires, robust connectors, and reliable insulation.

As a leader among Harness Manufacturing Companies In Vietnam, we ensure all products feature UL-certified wires, MIL-SPEC compliant cables, and premium-grade connectors like TE, MOLEX, and JST for superior quality.

- Perform Cleaning and Maintenance

Dust, grime, and moisture can degrade harnesses over time. Periodically clean connectors and wires using appropriate tools and cleaners to maintain connectivity and performance.

- Plan for Replacement and Upgrades

Even with proper maintenance, harness assemblies may eventually require replacement. Proactively upgrading to more advanced or durable solutions can enhance system performance and reliability.

Why Choose SINNHONG ELECTRONICS?

When it comes to Harness Manufacturing Companies In Vietnam, we stand out as a trusted partner. Here’s why:

- Superior Quality Assurance

We are ISO 9001 certified and adhere to strict quality management processes to deliver high-performance harness assemblies. Our products meet RoHS 2.0 regulations, ensuring safety and environmental compliance.

- Comprehensive Customization

Whether you need industrial control cable assemblies or SAE trailer plug wiring harnesses, we tailor solutions to meet your unique requirements. From material selection to configuration, our flexibility ensures you get precisely what you need.

- Competitive Pricing

Operating in Vietnam allows us to optimize production costs without compromising quality. By leveraging the favorable business environment, we offer competitive prices, solidifying our position as a leader among Harness Manufacturing Companies In Vietnam.

- Advanced Manufacturing Capabilities

Our 3,000 square meter facility in Vietnam is equipped with automation and semi-automation technologies. This enables us to produce harness assemblies quickly and efficiently, reducing turnaround times while maintaining precision.

- Wide Product Range

Our portfolio includes:

- Custom industrial control cable assemblies for factory automation and robotics.

- Weather-resistant ring terminal wire harnesses for outdoor use.

- SAE trailer plug wiring kits for automotive and agricultural applications.

- High-speed data transmission cables for industrial networks.

These versatile solutions serve industries like automotive, manufacturing, aerospace, and renewable energy, making us a one-stop shop for your harness needs.

- Focus on Innovation

Our dedicated R&D team continually improves designs and processes, ensuring that our products remain at the forefront of technological advancements.

- Excellent Customer Support

From initial consultation to after-sales service, we prioritize customer satisfaction. Our professional engineering team provides expert guidance at every stage, ensuring seamless integration of our harness assemblies into your systems.

Applications of Our Harness Assemblies

Harness assemblies are integral to various industries:

- Automotive: Secure electrical connections for vehicles and EV charging stations.

- Industrial Automation: Precise wiring for PLCs, SCADA systems, and motion control.

- Renewable Energy: Reliable connections for solar and wind energy systems.

- Aerospace: Lightweight, durable harnesses for critical systems.

As a top name among Harness Manufacturing Companies In Vietnam, we are dedicated to delivering tailored solutions for these and many other applications.

Harness assemblies are the backbone of modern connectivity, ensuring efficient and reliable operation across industries. With our commitment to quality, customization, and innovation, SINNHONG ELECTRONICS is your go-to partner among Harness Manufacturing Companies In Vietnam. Whether you need simple wiring solutions or complex, precision-engineered assemblies, our products are designed to exceed expectations.