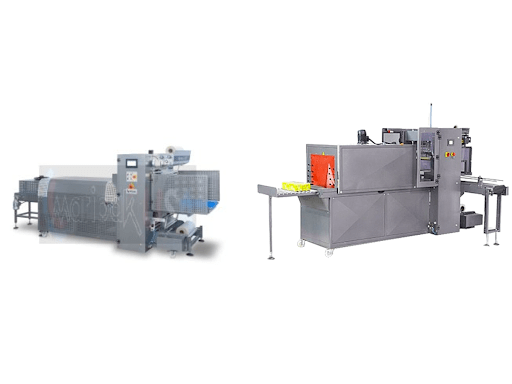

Polyolefin shrink equipment has become a cornerstone of modern packaging operations due to its versatility, clean finish, and suitability for a wide range of industries, including food, pharmaceuticals, electronics, and retail. At the heart of this equipment are two critical components: the sealing system and the shrink tunnel. Understanding how polyolefin shrink equipment works from a technical standpoint not only helps businesses optimize their packaging processes but also ensures better product protection, presentation, and shelf life.

What is Polyolefin Shrink Film?

Before diving into the mechanics of the equipment, it’s essential to understand the material involved. Polyolefin shrink film is a type of polymer-based plastic made from a blend of polyethylene and polypropylene. It is known for its strength, clarity, and flexibility. Unlike PVC shrink film, polyolefin is food-safe, emits fewer odors when heated, and is more resistant to punctures and temperature changes, making it ideal for high-speed, high-volume packaging environments.

Polyolefin film shrinks uniformly when exposed to heat, conforming tightly around the product. This process requires specialized machinery—polyolefin shrink equipment—which typically includes a sealing system and a shrink tunnel.

Sealing Process: The First Step in Shrink Packaging

The packaging process begins with the sealing stage. In most systems, products are placed within a polyolefin film that has been pre-formed into a tube (center-folded) or flat sheet. The film surrounds the product and is then sealed to enclose it.

There are several types of sealing machines used in polyolefin shrink equipment:

- L-Bar Sealers: The most common type used in medium to high-volume applications. The “L” shaped bar cuts and seals the film around the product in one motion.

- Impulse Sealers: Use a brief burst of electrical current to heat the sealing wire. These are often used for thinner films or smaller packaging volumes.

- Continuous Side Sealers: Ideal for high-speed operations, these machines create a continuous seal along the side of the film, allowing for greater throughput.

The seal must be precise and strong enough to hold up during the next stage—heat shrinking. Poor seals can lead to product exposure or packaging failure during transit.

The Shrink Tunnel: Where the Magic Happens

Once the product is enclosed in sealed polyolefin film, it moves into the shrink tunnel. This is where the real transformation takes place. A shrink tunnel is essentially a heated chamber equipped with conveyor belts, fans, and temperature controls. Its primary purpose is to apply controlled heat to the wrapped product, causing the polyolefin film to contract and conform tightly to the shape of the item.

Here’s how it works:

- Heat Application: As the wrapped product enters the shrink tunnel, it’s exposed to high temperatures—typically between 300°F and 400°F (150°C to 200°C). The temperature varies depending on the film thickness, product size, and desired finish.

- Air Circulation: Internal fans circulate the hot air evenly around the product. Uniform airflow is essential for consistent shrinking, especially for irregularly shaped or multi-item packages.

- Film Contraction: Polyolefin film is designed to shrink when heated. The heat softens the film, which then begins to contract. Because the film was applied loosely during the sealing stage, this contraction creates a snug, tamper-evident finish around the product.

- Cooling and Set: Once the product exits the tunnel, it begins to cool almost immediately. This rapid cooling helps the film “set” in place, locking the shape and providing a durable outer layer.

Key Advantages of Polyolefin Shrink Equipment

There are several reasons businesses prefer polyolefin shrink equipment over other packaging systems:

- Product Versatility: Works well for single items, multipacks, and even oddly shaped products.

- Clarity and Shelf Appeal: Polyolefin film is crystal-clear, making it ideal for retail packaging.

- Durability: Resistant to tearing, puncturing, and environmental factors such as humidity.

- Safety and Compliance: Polyolefin is FDA-approved for direct food contact and emits fewer harmful fumes during processing.

- Efficiency: Modern shrink tunnels and sealers can handle thousands of packages per hour with minimal operator intervention.

Maintenance and Operational Considerations

To maintain optimal performance, regular maintenance of polyolefin shrink equipment is necessary. This includes checking sealing wires, cleaning the shrink tunnel of film buildup, calibrating temperature settings, and ensuring that airflow systems remain unobstructed. Operators should also be trained in the specific handling and setup procedures for the equipment to prevent downtime and reduce material waste.

Conclusion

Polyolefin shrink equipment plays a critical role in modern packaging lines by providing clean, secure, and professional wrapping for a broad range of products. From the precision of the sealing system to the controlled environment of the shrink tunnel, each step is engineered to deliver maximum efficiency and product protection. For businesses looking to improve their packaging operations, investing in high-quality wrapping machines that utilize polyolefin film is a smart and future-proof choice.