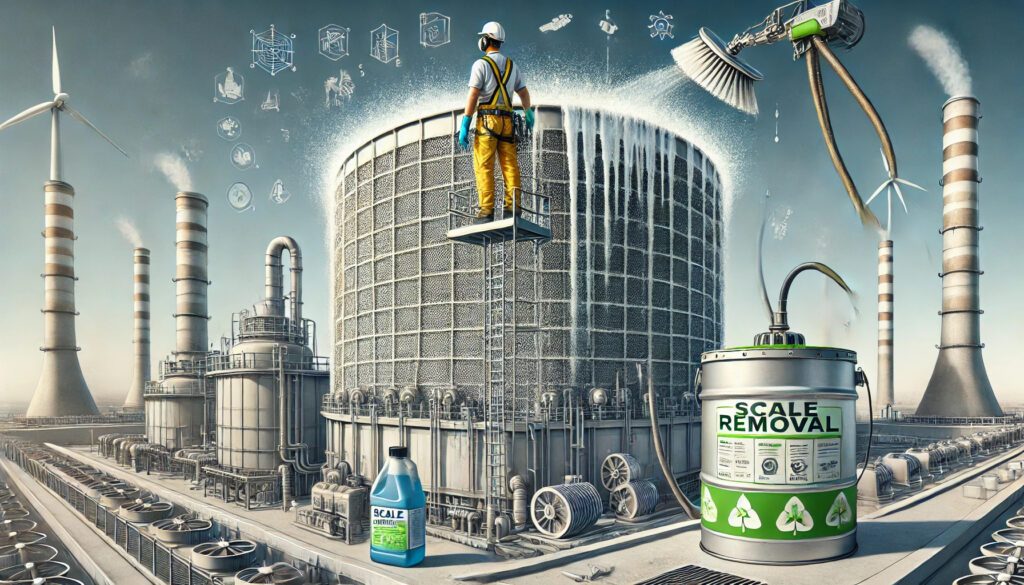

Cooling towers are indispensable in industrial and commercial cooling systems, providing essential heat dissipation for processes such as power generation, manufacturing, and HVAC operations. However, their efficiency and longevity can be severely compromised by scale formation—a common issue that demands immediate attention. This article delves deep into the science, challenges, and effective strategies for cooling tower scale removal, ensuring long-term operational success and cost efficiency.

What Is Cooling Tower Scale and Why Is It a Problem?

Scale in cooling towers is primarily composed of mineral deposits, such as calcium carbonate and magnesium salts, that precipitate out of water due to changes in temperature, pH levels, or water chemistry. Over time, these deposits accumulate on critical components, including heat exchangers, piping, and tower surfaces.

Problems Caused by Scale:

- Reduced Heat Transfer Efficiency: Scale acts as an insulator, impeding the cooling system’s ability to transfer heat effectively.

- Higher Energy Costs: Systems must work harder to achieve the same cooling effect, leading to increased energy consumption.

- System Blockages: Severe scale buildup can obstruct water flow, reducing system capacity and efficiency.

- Corrosion Risk: Deposits can trap water and chemicals, accelerating corrosion and causing equipment damage.

- Shortened Equipment Lifespan: Persistent scale issues can result in frequent repairs or early replacement of components.

Comprehensive Scale Removal Techniques

1. Mechanical Cleaning Methods

Mechanical cleaning is often the first line of defense for scale removal. This hands-on approach involves physical removal of scale deposits and is ideal for heavy buildup.

- Brushing and Scraping: Manual tools like wire brushes are used to scrub away visible deposits.

- Hydro Jetting: High-pressure water jets effectively dislodge hardened scale without damaging the underlying surfaces.

- Sandblasting: In severe cases, abrasive blasting can remove tenacious deposits, restoring surfaces to their original condition.

Advantages: Immediate results and suitability for localized problem areas.

Challenges: Labor-intensive and may require system downtime.

2. Chemical Descaling

Chemical cleaning involves the use of specialized solutions to dissolve scale. This method is efficient for removing deposits in hard-to-reach areas.

- Acid-Based Descalers: Commonly used chemicals like hydrochloric or citric acid dissolve mineral deposits efficiently.

- Alkaline Cleaners: These solutions address silica and phosphate-based scales.

- Biodegradable Descalers: Environmentally friendly chemicals minimize ecological impact while maintaining effectiveness.

Best Practices for Chemical Cleaning:

- Conduct a thorough system evaluation to choose the appropriate chemical.

- Follow safety protocols, including wearing protective gear.

- Ensure proper neutralization and disposal of chemicals after cleaning.

3. Water Treatment and Softening

Effective water treatment reduces the likelihood of scale formation, complementing removal efforts.

- Softening Systems: These devices reduce water hardness by removing calcium and magnesium ions.

- Anti-Scaling Agents: Chemicals introduced into the system prevent mineral crystallization and deposition.

4. Ultrasonic and Electromagnetic Methods

These modern, non-invasive technologies use sound waves or electromagnetic fields to disrupt scale formation.

- Ultrasonic Descalers: Emit sound waves that prevent minerals from bonding to surfaces.

- Electromagnetic Devices: Alter the mineral composition of water to inhibit deposition.

Preventive Measures for Long-Term Scale Control

Preventive strategies are critical for maintaining the performance of cooling tower systems.

- Regular Water Quality Monitoring: Test water for parameters like hardness, alkalinity, and pH levels to detect potential scaling issues early.

- Proper System Design: Ensure that your cooling tower is designed to minimize areas of low flow and stagnant water.

- Routine Maintenance Schedule: Perform regular inspections and cleanings to prevent minor scale buildup from becoming a major issue.

- Automated Control Systems: Use automated dosing systems to maintain precise chemical balances in cooling water.

Benefits of Proactive Scale Management

Implementing a robust scale management program not only solves existing problems but also yields long-term benefits, including:

- Energy Savings: Reduced scale translates to lower energy requirements and operating costs.

- Improved Operational Reliability: Minimizing downtime and equipment failures ensures consistent performance.

- Extended Equipment Lifespan: Protecting components from scale and corrosion delays the need for replacements.

- Environmental Sustainability: Optimized systems reduce water and energy waste, contributing to greener operations.

Conclusion

Effective cooling tower scale removal is essential for maintaining system efficiency, reducing operational costs, and ensuring equipment longevity. While mechanical, chemical, and modern ultrasonic methods provide solutions for existing scale issues, prevention is always better than cure. Combining advanced technologies, routine maintenance, and water treatment programs offers a holistic approach to scale management.

By adopting these techniques, industries can achieve reliable cooling performance and contribute to sustainable practices. Whether you’re dealing with severe scaling or looking to implement preventive strategies, investing in the right solutions today can save significant time and resources in the future.

Would you like guidance on implementing any of these methods or information on advanced water treatment systems?