Shrink wrap machines play a crucial role in the packaging process, helping small businesses protect and present their products professionally. Whether you run a retail store, an e-commerce business, or a manufacturing unit, using a shrink wrap machine can enhance your product’s appearance and ensure durability during shipping. Finding the right shrink wrap machine for sale can be challenging, especially when you need to balance quality, affordability, and functionality. This guide explores the best shrink wrap machines for small businesses and highlights key factors to consider before making a purchase.

Why Small Businesses Need a Shrink Wrap Machine

Shrink wrap machines offer several benefits to small businesses:

- Improved Product Presentation: Shrink-wrapped products have a clean, professional look, making them more appealing to customers.

- Protection Against Contamination: Shrink wrap prevents dust, moisture, and dirt from affecting the product, ensuring that items remain intact.

- Reduced Packaging Costs: Investing in a shrink wrap machine can save money on packaging materials over time.

With these advantages, small businesses can enhance their product value while optimizing operational efficiency.

Types of Shrink Wrap Machines Suitable for Small Businesses

When looking for a shrink wrap machine for sale, it’s essential to choose one that aligns with your business needs. Below are the most common types of shrink wrap machines ideal for small businesses:

1. Manual Shrink Wrap Machines

Manual shrink wrap machines are affordable and easy to operate, making them a popular choice for small businesses with low to medium production volumes. These machines typically consist of a heat sealer and a heat gun or shrink tunnel. Operators manually place the product in the shrink film, seal it, and apply heat to shrink the film around the product.

Pros:

- Low initial investment

- Easy to use and maintain

- Suitable for small batches

2. Semi-Automatic Shrink Wrap Machines

Semi-automatic machines offer a balance between speed and manual control. These machines automate part of the wrapping process, such as sealing, while requiring the operator to initiate the shrink process manually. They are ideal for businesses that handle moderate production volumes.

Pros:

- Faster operation than manual machines

- Suitable for growing businesses with increasing demand

- Better consistency in wrapping quality

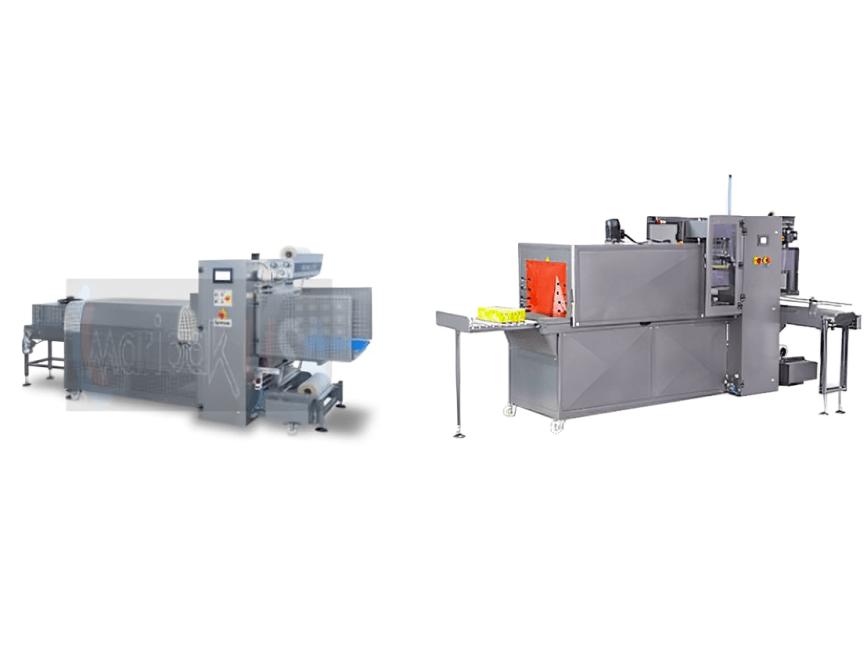

3. Automatic Shrink Wrap Machines

Automatic shrink wrap machines handle the entire wrapping process with minimal operator intervention. These machines can seal and shrink multiple products at once, significantly increasing production efficiency. While they are more expensive, they are a worthwhile investment for businesses with high-volume packaging needs.

Pros:

- High-speed operation

- Consistent sealing and shrinking quality

- Ideal for large-scale production

Top Shrink Wrap Machines for Small Businesses

Here are some of the best shrink wrap machines available for small businesses:

1. Impulse Sealer with Heat Gun

This manual option is affordable and effective for small-scale operations. It is perfect for businesses packaging a variety of products, such as cosmetics, small electronics, or food items.

2. L-Bar Sealer with Shrink Tunnel

L-Bar sealers provide a clean seal and, when paired with a shrink tunnel, they ensure even shrinking around the product. These machines are ideal for businesses that require professional-looking packaging and moderate production speeds.

3. I-Bar Sealer with Heat Gun

I-Bar sealers are compact and easy to use, making them suitable for small businesses that need to package irregularly shaped items.

4. Automatic L-Bar Sealer with Tunnel

For businesses with higher production demands, automatic L-Bar sealers combined with shrink tunnels offer maximum efficiency and consistency.

Factors to Consider When Buying a Shrink Wrap Machine

When evaluating a shrink wrap machine for sale, consider the following factors to ensure that you make the right choice:

- Production Volume: Choose a machine that matches your business’s packaging output. Manual machines are ideal for low volumes, while automatic models suit higher production needs.

- Film Type and Compatibility: Ensure the machine supports the type of shrink film you plan to use, such as PVC, polyolefin, or polyethylene.

- Budget and ROI: Consider the machine’s initial cost and long-term savings to determine the return on investment.

- Space and Portability: Evaluate the available space in your facility and choose a machine that fits without overcrowding the workspace.

Conclusion

Choosing the best shrink wrap machine for your small business can enhance your packaging process, improve product presentation, and protect items during shipping. Whether you opt for a manual, semi-automatic, or automatic machine, consider your production volume and business needs to make an informed decision. If your business grows, transitioning to a shrink wrap machine industrial model can further streamline your operations and accommodate higher demands effectively.